Cogeneration and Combined Heat and Power Systems

It is common to use digester gas/ biogas to help power co-generation and combined heat and power systems.

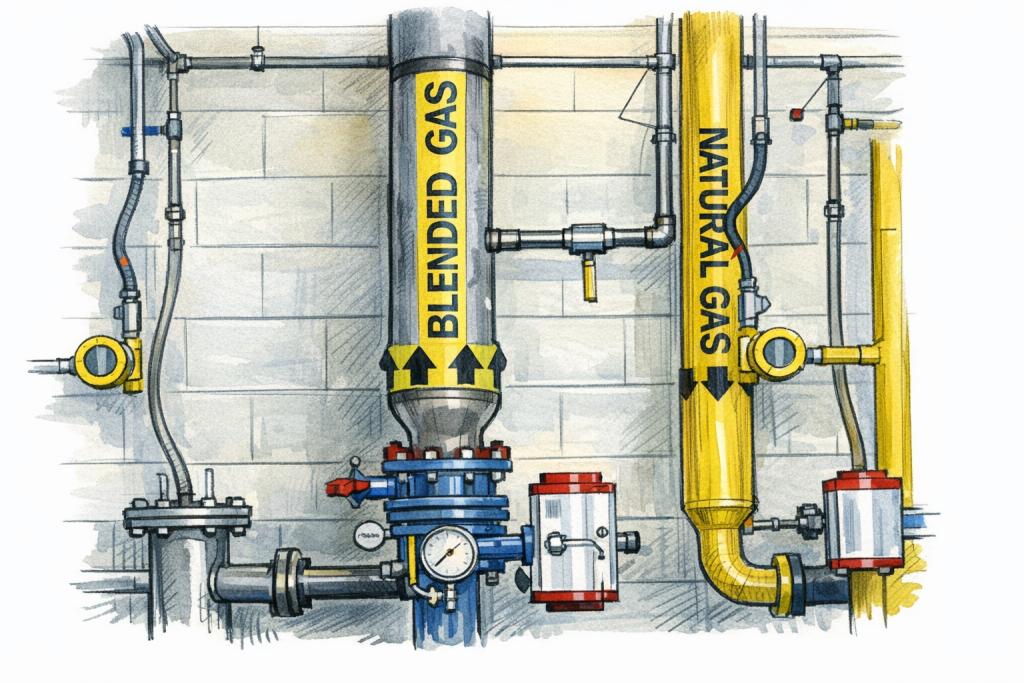

Depending upon the amount of digester gas/biogas produced at any given time, a supplemental supply of natural gas may be required. It is essential to understand the calorific value of the digester gas feed in order to supplement it with the correct amount of natural gas, maintaining a proper ratio to ensure the calorific value of the blended gas being fed to the engine. Mass flow measurements maintain this proper ratio in order to achieve higher energy efficiencies. Volumetric flow measurements are inadequate.

Capacity demand requires instrumentation with flow turndown capabilities as high as 100:1. Gas specific calibrations ensure overall performance of the mass flow meter under actual field conditions. The use of flow conditioners (Vortab VIP) allows for reducing the footprint of meter runs.

For such an application containing a mix of CO2, Methane and Hydrogen Sulfide, a ST80 with ATEX Ex d has been used on a 6 inch pipe with up to 250 cubic meters per hour of the mixed gas flowing through.