Visual Monitoring and Foam Control in Vessels

Bioprocess foaming occurs throughout a cell culture and must be constantly monitored to prevent filter blockages, overflow and excess foam issues. The standard mitigation technique is the visual inspection and injection of antifoaming agents which necessitate further downstream processing. Operators must decide upon antifoam injection based on what is seen at these distinct timepoints.

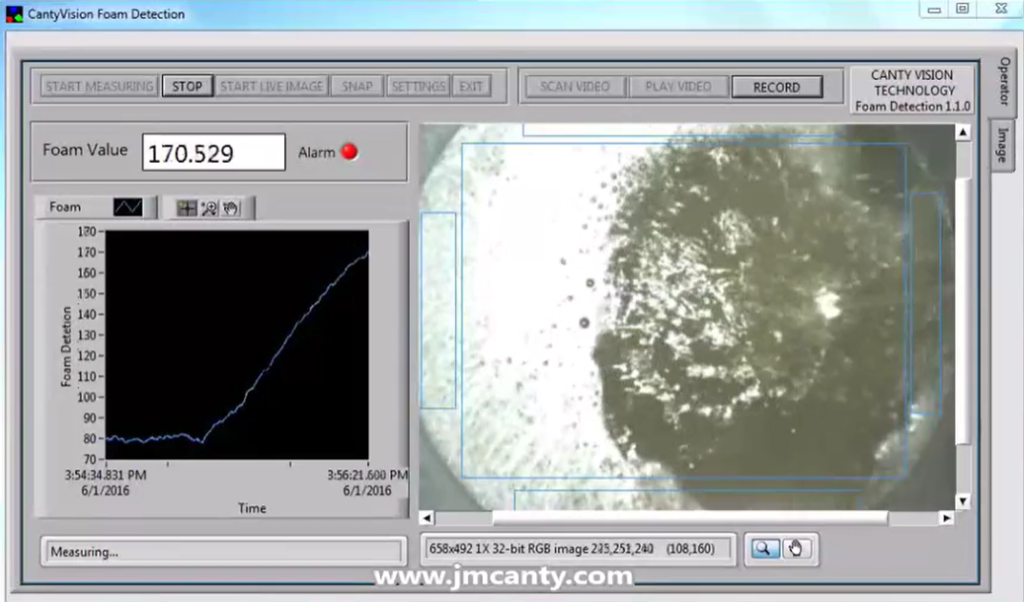

Automation of these antifoam inputs can thus reduce downstream processing and mitigate the risk of over foaming. The Canty technique replaces the visual inspection with an automated live image achieved with a camera. Canty foam control operates using a vision based principle to capture live images of the process as foam is forming. The CantyVision software suite uses advanced image processing techniques to detect light reflection from the bubbles of the foam itself.

Such foaming is not only present in biopharmaceutical vessels, they are also present in digester tanks in the Wastewater industry.

J.M. Canty provides different cameras to suit the applications in the different industries – the Biocam™ for applications with sanitary fittings and the Canty Process Cameras for the vessels with regular flange connections such as that in the Wastewater industry – but both look out for similar same parameters in the image captured by the video stream from the cameras.