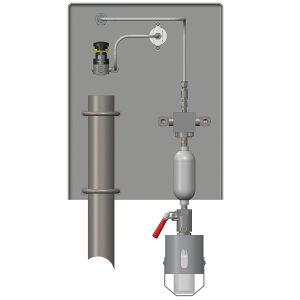

Models

PIBSS

Warranty

1 Year

- Guarantees repeatable sample volume

- Zero dead volume

- Replaceable process and vent needles

- Suitable for high process pressures

- SENSOR Needle Evacuation System standard

- Eliminates over filling of sample container

The SENSOR Pressure Isolating Basic Sampling System (PIBSS) is designed for safe and reliable closedloop “grab” sampling of liquids at process pressures greater than 150 psig (X bar) or for any application for which the operator wishes to collect a repeatable volume of process liquids. The SENSOR sample valve is designed to operate under continuous flow via a bypass or parallel line off the main process piping. The inclusion of a secondary isolation valve ensures that the sample container is not exposed to process pressure.

- Highly customizable based on process conditions and operator requirements

- Primary Flow-Thru Sample Valve features a side-ported needle valve with packing below the threads; ensuring that the stem will not seize due to process build up.

- Side-ported Vent Needle prevents plugging of vent port

- Secondary Isolation Valve below Volume Cylinder prevents bottle exposure to process pressure

- Can be designed to produce repeatable sample volume

- 316L standard material; other materials available

- Replaceable Process and Vent Needles

- Non-metallic bottle shroud protects operator in case of shattered bottle

- Customized Operation and Installation Manual for each system

- Optional SENSOR Sampling CONCENTRIC single needle design is available