Measuring hydrogen coolant flow rates in power plants

Hydrogen is the industry’s most efficient coolant, particularly for generators (over 100 mW) because

hydrogen has a 15 times higher heat/thermal conductivity efficiency compared to air.

However, the size of a H2 molecule is 10 times smaller than a nitrogen molecule, for example, and it is combustible. A typical generator therefore, has many potential leak paths and small hydrogen molecules are far more likely to find those leak paths. Being lighter than air, the escaping H2 could rise and accumulate in the roof space of the power plant and creating an unsafe environment.

Thermal mass flow meters are ideal to measure the flow rate of hydrogen in such applications.

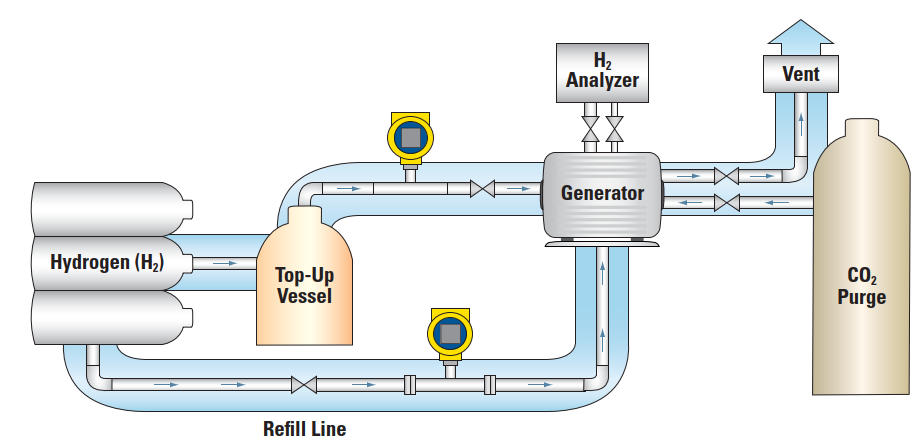

FCI’s ST75V Series Thermal Mass Flow Meter can be installed between the top-up vessel and the generator per the below figure. The thermal meter measures direct gas mass flow without the need for separate temperature and pressure transmitters as well as a flow computer. The meter’s standard accuracy is ± 1% of reading + 0.5% of full scale.

Operating over a wide flow range with a minimum flow rate as low as 0.01SCFM [0,28 Nl/min] and a wide turndown

ratio of 100:1, the flow meter’s wide turndown range-ability allows the plant team to measure the H2 flow more accurately to the generator under all power demand conditions: from very low flows, or leaks to accidental high flow leaks.

With the option of an all-welded sensor design, it also helps to eliminates any potential H2 leak paths.

This in-line meter also features a unique built-in VORTAB flow conditioner, which is welded inside the assembly to allow extremely short installation length of 9D (9 x nominal diameter) without sacrificing accuracy.

This article is an excerpt from the original technical publication by Fluid Components International beloiw.