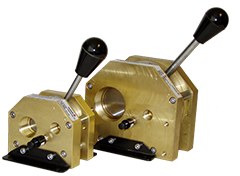

The Smartflow® SWAP® Valve is a simple, manually selectable device that supplies cooling water to the mold during processing. Secondly, it supplies air to purge the water from the mold, cooling lines, Supply and Return manifolds prior to tool change. And, it provides a manual vent to release built-up air pressure within the cooling water loop, after purging. The 3-position shear valve is a proven design. Ball detents, with approximately 15 pounds breakaway force, retain the valve selector handle in the chosen position (WATER, PURGE or VENT). An included check valve should be installed in the return line downstream from the Return manifold to prevent backflow to the mold. Tubing may be connected to the manual vent-drain port so any residual water after the purge cycle can be drained into a suitable container or drain.

An optional spring-loaded, locking mechanism on the valve selector assembly is available for molders who require additional protection from accidental valve movement.

Application

The SWAP® Valve is well-suited for cooling water Supply lines up to 2-inch NPT on frequently changed tools that are hung on injection molding machines. It is permissible to adapt 0.75″, 1.25″, and 1.5″ line sizes providing adequate cooling water flow can be achieved. Typical mounting is on the press frame or the safety door frame. Mounting on any suitable surface, such as a platen, mold or manifold stand is acceptable.

Operation

For Normal Processing:

- Select WATER.

- Cooling Water is available to the Supply manifold

- Purge Air is blocked

To evacuate cooling water:

- Select PURGE.

- Purge Air is available to the supply manifold

- Cooling Water is blocked

To bleed-off trapped pressure and drain residual water:

- Select VENT.

- Press Manual Vent-Drain valve

- Purge Air is blocked

- Cooling Water is blocked

Molder Benefits

- Timesaving: Saves 15-20 minutes of unproductive tool change time by eliminating the tasks of draining multiple Supply and Return hoses plus cleaning-up water spills.

- Tool Condition: Protects tools from corrosion build-up during downtime and storage by evacuating water quickly and thoroughly.

- Supply Line ID: Permits fast identification of Supply lines by noting which manifold is connected to the SWAP® Valve.

- Water Shut-Off: SWAP® Valve shuts-off Supply water conveniently near the machine control, rather than with conventional ball valves on the water drops/risers or Supply manifold, typically located at the opposite side of the press.

- Full Port Design: Permits maximum cooling water flow at minimum pressure drop.

- Safety-Housekeeping: Eliminates root cause of accidents around the press by keeping personnel and floors dry.

- Optional Positive Lock: Eliminates accidental movement of valve selector handle.