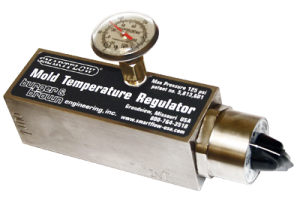

The Smartflow Mold Temperature Regulator effectively controls mold cooling water temperature between 80°F and 120°F (27° and 49°C) to maintain a steady mold temperature.

Installed to control water flow exiting an injection mold, the Mold Temperature Regulator quietly recovers waste heat from the resin shot, working without electricity to reduce shop floor clutter, and cut production costs. In many cases, it is a simple, inexpensive substitute for a conventional electric mold heater. Cooling water temperature always corresponds to higher mold (steel) temperatures (for example: 120°F water temperature may result in 180°F mold temperature).

Pressure & Temperature

Traditionally, high turbulent flow rates are used in cooling water loops to achieve acceptable heat transfer rates from the mold. High turbulent flow rates are irrelevant when using the Smartflow Mold Temperature Regulator. It regulates cooling water flow leaving the mold to achieve Set Point Temperature.

The unit is also unaffected by supply cooling water pressure and temperature. For example, it automatically compensates for temperature changes of cooling tower water between night and day.

Product Features

- Multiple zone control – using several regulators or an optional inlet manifold facilitates effective zone control

- Unaffected by pressure changes – the Mold Temperature Regulator uses the thermal expansion principle for operation

- Handles tower water temperature changes – modulates flow to control cooling water temperature

- In-Line mounting – installs easily without additional hardware

- Cost of ownership – typically 1/6 the cost of a conventional electric mold heater

- Maintenance free – few internal parts for trouble-free operation

- Energy saving – it uses no electricity, conserving precious energy dollars

- Small size – cleans up shop floor clutter: no hoses or power cords to trip over

- Integral dial thermometer – verifies Set Point temperature

- Optional inlet manifold – provides temperature control for multiple zones with one regulator

Principle of Operation

The Smartflow Mold Temperature Regulator works on the principle of thermal expansion. It is connected to the return lines of the mold cooling water loop. A simple bellows and range spring capsule senses the temperature of the water leaving the mold and compares it to the Set Point temperature. The Set Point is easily adjusted by rotating the pointer knob to the desired water temperature value on the calibration scale. The dial thermometer provides visual verification of the setting.

Note: A discrete cooling water temperature always corresponds to a hotter mold (steel) temperature. When the water temperature leaving the mold is hotter than the Set Point, the internal valve modulates toward open, cooling water flow rate increases, and cooling water temperature decreases to stabilize at the Set Point. When the water temperature leaving the mold is cooler than the Set point, the internal valve modulates toward close, cooling water flow rate decreases, residency time in the mold increases and cooling water temperature rises until stabilizing at the Set Point. The valve never completely closes. Note: The Mold Temperature Regulator recovers waste heat energy from the resin shot and transfers it to heat the cooling water and the mold. The Mold Temperature Regulator does not generate heat, and it does not function as a chiller.

Applications

The Mold Temperature Regulator is generally suitable for mold applications where the supply water is cooler than the mold and where the resin shot size is sufficient to heat the mold in the first few shots.

Control Feed Throat Condensation by installing a Mold Temperature Regulator in the barrel cooling loop. Set the dial once on the MTR, and allow it to maintain temperature and eliminate condensation in the resin.