The BPRV offers the highest flow capacity and convenient in-line installation. After activation, the valve is manually reclosed and the pin replaced while the valve remains bolted between pipe flanges. This dramatically reduces plant downtime and personnel exposure. The pin is accessible in a lockable enclosure containing the BPRV mechanism. Valve sizes range from 2 inches (50mm) to 60 inches (1,500mm). Alternative, larger sizes available upon request.

The BPRV is available with a standard range of sizes and set pressures designed to suit applications that are compatible with ANSI 150, DIN PN 10 or similar flange specifications. In addition to these standard specifications, the BPRV is capable of meeting a wide range of dedicated customer requirements that have already included:

- High set pressures: Over 3,700 psi (255bar) in a 6 inch (150mm) nominal size installed between ANSI 900 flanges

- Low set pressure: 1 psig (68.9mbar) in a 24 inch (600mm) nominal size

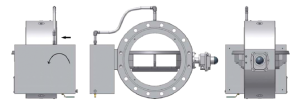

3 Primary BPRV Components

Rotating disk: A rotating disk normally closes the flow path and turns through 90 degrees in response to an overpressure/underpressure condition. The rotating disk is constructed from metal and has a hollow design. This maximizes the flow path through the BPRV and ensures the stability of the disk during normal service and at the time of opening.

Flanged body: A flanged body contains the rotating disk, holding it in place using shaft connections that are sealed within the body and pass through bearings to permit free rotation of the disk within the body. The body is a 1-piece design with no constructional welds or other potential external leak paths.

External enclosure and mechanism: The external enclosure and mechanism provides the set pressure control for the BPRV. The mechanism is designed to resist the turning moment of the disk shaft during normal service pressure conditions. When the desired set pressure is reached, the mechanism releases the disk due to the function of a buckling pin which has been built with sufficient strength to resist disk rotation until that point. The mechanism is contained within a stainless steel enclosure. The enclosure door includes a seal to permit service under severe environmental conditions.