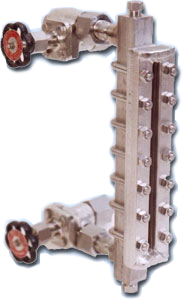

Simco Reflex liquid level gauges are designed to operate based on the difference in the refractive indices of liquid and vapour. The liquid flows through the gauge chamber behind the viewing glass located on only one side of the instrument and which is clamped to the gauge body. The viewing glass is made from toughened borosilicate glass and has prismatic right-angled grooves on the side facing the liquid and vapour space. Light entering from outside the gauge is then absorbed or reflected depending upon whether it strikes the liquid or vapour space. When liquid is present the glass will appear black where it is in contact with the process medium and when no liquid is present the glass is silvery / white thus the level can be seen.

This type of gauge is used for measuring the total liquid level of clean fluids in a vessel.

Typical Vessel Connection

- Threaded – ½”, ¾” NPT (Union connections avail.)

- Flanged – ½”, ¾”, 1”, 1.5”, 2” & 3” ANSI Class 150#, 300#, 600#

Typical Gauge Connection

- Threaded – ½”, ¾” NPT (Union connections avail.)

- Socket Welded – ½”, ¾”

- Butt Welded – ½”, ¾”

Typical Vent / Drain Connection

- Threaded – ½”, ¾” NPT

- Flanged – ½” & ¾” ANSI Class 150#, 300#, 600#

Selection of Available Accessories

- Non-Frosting Extention – For low temperature applications protecting against the build up of frost.

- Calibrated Scale – Manufactured from traffolyte / 316 stainless steel and engraved with units which reflect individual clients requirements.

- Internal Heating System – A small diameter tube containing the heating system which is then in direct contact with the process and situated in the centre of the chamber.

- External Heating System – The medium may be heated or cooled using either a square or small diameter tube attached to the outside of the chamber. Connections are ¼” NPT female.