Non-contact laser level measurement solutions

Industries served

- Mining and construction

- Aggregates

- Fertilizers

- Chemicals

- Pulp and paper processing

- Oil & gas

- Power generation

- Food and beverage

- Water and wastewater

Customer benefits

- Non-contact

- Maintenance free

- Narrow beam not affected by surrounding structures

- No echo mapping required

- Very flexible installation, can be aimed at an angle

- Range up to 200 m

- Very accurate

- Rapid response

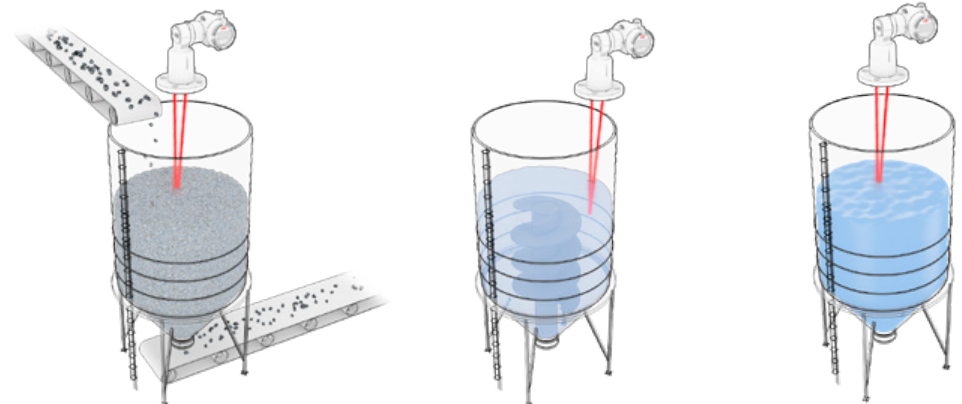

Level measurement with laser technology

Using a time-of-flight calculation, the LLT100,

LM80, and LM200 can accurately measure the

distance to the targeted surface.

These level transmitters use invisible, eye-safe,

infrared laser pulses to measure the distance

to the surface. The on-board microprocessor

calculates the distance by multiplying the known speed of light by the travel time of the laser pulse from the transmitter to the surface and back.

The laser beams have very little divergence (<0.3°) so accurate targeting is easy even in silos or vessels that have internal structures. Also, the narrow beam does not interact with local structures or build-up on vessel walls, making measurements very reliable even when the environment changes. This means no reconfiguration, no down-time and reduced lifetime costs.

Made for industrial applications

- Measures through dust and fog

- Approved for hazardous areas

- Certified for high pressures