Requirements

Ability to handle the drying process effectively without wasteage.

Solution

The latest in imaging camera technology, combined with high intensity LED lighting, is mounted to your filter dryer vessel to provide an unrivalled remote view from the control room into your process. A jet spray ring system is incorporated to ensure the camera view through the fused glass process barrier is clean at all times, ensuring a continuous clear view of your process.

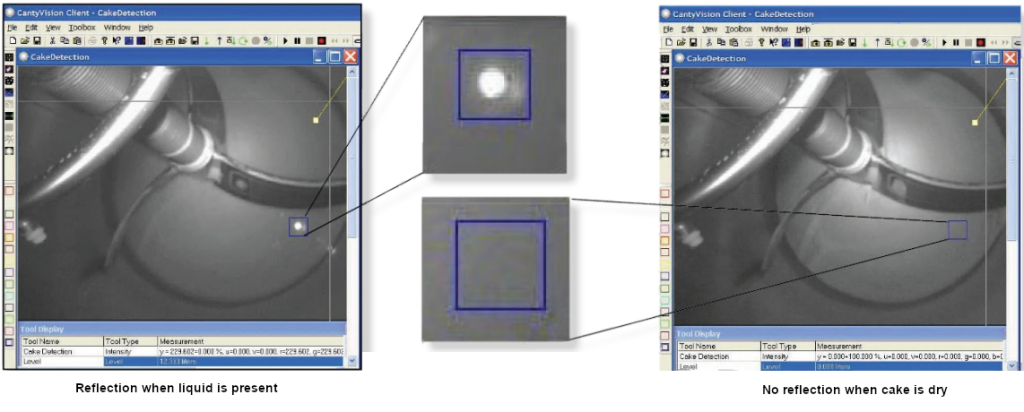

Using an intensity measurement algorithm, CantyVision™ imaging software can be configured to determine the exact filtration end point, and send a signal to the DCS via OPC or 4-20mA. The liquid surface reflects a bright spot created by the vision system’s integral light source. The wet cake surface does not, and so the exact transition point at which the cake emerges is determined.

This avoids the possibility of a cracked cake surface due to drying out of the product, and also allows for a more efficient washing regime, which in turn increases throughput by reducing the number of washing cycles required.